The Ultimate Guide to SWR Drainage Systems: What Every Developer Needs to Know

Introduction: What Are SWR Drainage Systems and Why They Matter

SWR (Soil, Waste, and Rainwater) drainage systems are essential components of modern plumbing and infrastructure, designed to efficiently manage and transport wastewater, soil water, and rainwater. Unlike traditional drainage systems, SWR systems are engineered for optimal flow, leak-proof connections, and long-term durability. They are widely used in residential, commercial, and industrial projects, ensuring effective waste management and environmental sustainability. With growing urbanization, strict building regulations, and the need for efficient drainage solutions, SWR systems have become the preferred choice for large-scale construction projects. This comprehensive guide explores everything developers need to know about SWR drainage systems, including their types, benefits, applications, installation techniques, and compliance with new building regulations.

What Are SWR Drainage Systems?

SWR drainage systems are designed to manage soil water (wastewater from toilets), waste water (from sinks, showers, and kitchens), and rainwater. These systems include a network of pipes, fittings, traps, and accessories that efficiently transport waste to sewage systems or rainwater harvesting units. Made from high-quality PVC or uPVC, SWR systems are corrosion-resistant, leak-proof, and durable, ensuring efficient drainage and environmental protection.

Types of SWR Drainage Systems and Their Applications

SWR drainage systems are categorized into three main types: Soil Drainage Systems, Waste Water Drainage Systems, and Rainwater Drainage Systems. Each type is designed to handle specific types of waste, ensuring efficient and safe disposal. Understanding the types and applications of SWR drainage systems helps developers select the right solutions for their projects, ensuring optimal performance and regulatory compliance.

Soil Drainage Systems: Managing Wastewater from Toilets

Soil drainage systems are designed to transport wastewater from toilets, urinals, and bidets to the sewage system. They include soil pipes, vent pipes, and fittings that ensure a leak-proof and odor-free connection. These systems are designed with a smooth inner surface for optimal flow and resistance to clogging. They are used in residential, commercial, and industrial buildings to maintain hygiene and environmental safety.

Waste Water Drainage Systems: Efficient Disposal of Kitchen and Bathroom Waste

Waste water drainage systems handle greywater from sinks, showers, bathtubs, and kitchen drains. They are designed to transport non-toxic waste efficiently and safely to the sewage system or wastewater treatment units. These systems include waste pipes, traps, and fittings that prevent backflow, leaks, and odor. They are essential for maintaining hygiene and preventing contamination in residential and commercial buildings.

Components of SWR Drainage Systems

SWR drainage systems consist of various components that work together to ensure efficient waste management, leak-proof connections, and long-term durability. The essential components include Pipes, Fittings, Traps, Vent Pipes, and Accessories. Each component is engineered to withstand high pressure, corrosion, and environmental stress. Understanding the functions and types of SWR components helps developers design efficient and reliable drainage systems.

SWR Pipes: Ensuring Optimal Flow and Leak-Proof Connections

SWR pipes are designed with a smooth inner surface to optimize flow and prevent clogging. They are made from high-quality PVC or uPVC, ensuring durability, corrosion resistance, and leak-proof connections. There are two main types of SWR pipes: Socketed Pipes and Plain End Pipes. Socketed pipes are designed for easy installation with rubber ring joints, while plain end pipes require solvent cement welding for leak-proof connections.

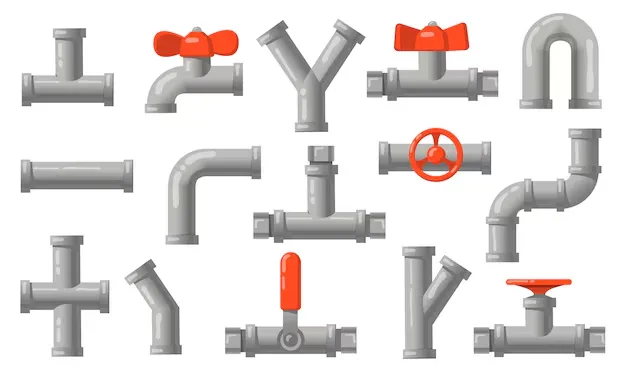

Fittings and Traps: Maintaining Hygiene and Preventing Backflow

Fittings and traps are essential for maintaining hygiene and preventing backflow, leaks, and odors. They include Bends, Couplers, Reducers, Tees, and Vent Cowlings. Traps, such as P-Traps, S-Traps, and Bottle Traps, retain a water seal that prevents sewer gases from entering the building. Proper selection and installation of fittings and traps ensure efficient drainage and environmental safety.

Benefits of Using SWR Drainage Systems in Large-Scale Projects

SWR drainage systems offer several benefits, making them the preferred choice for modern construction projects. They provide Leak-Proof Connections, Corrosion Resistance, Easy Installation, and Low Maintenance. Additionally, SWR systems are environmentally friendly, recyclable, and compliant with modern building regulations. This section explores the benefits of SWR drainage systems, highlighting their advantages over traditional drainage solutions.

Leak-Proof and Corrosion-Resistant Design

SWR drainage systems are designed with leak-proof joints and corrosion-resistant materials, ensuring long-term durability and environmental protection. The use of high-quality PVC and uPVC prevents chemical reactions, rust, and degradation, ensuring a reliable and safe drainage system. Additionally, the smooth inner surface prevents clogging, reducing maintenance costs and enhancing operational efficiency

Easy Installation and Low Maintenance

SWR drainage systems are lightweight and easy to install, reducing labor costs and installation time. They use push-fit joints and rubber ring seals for quick and secure connections, eliminating the need for welding or threading. Additionally, SWR systems require minimal maintenance due to their clog-resistant design and corrosion-proof materials, ensuring long-term cost savings and reliability.

Compliance with Building Regulations: Ensuring Safety and Sustainability

SWR drainage systems comply with modern building regulations, ensuring safety, hygiene, and environmental sustainability. They meet international standards, including IS 13592, ISO 9001, and BS EN 1329, ensuring quality, reliability, and safety. Additionally, SWR systems are designed for eco-friendly waste management, supporting green building certifications and sustainable development. This section provides insights into regulatory compliance and how SWR systems ensure safety and sustainability.

Meeting International Standards and Certifications

SWR drainage systems comply with international standards, including IS 13592 (Indian Standard), ISO 9001 (Quality Management), and BS EN 1329 (European Standard). These certifications ensure product quality, safety, and reliability, ensuring compliance with building regulations. Choosing certified SWR systems ensures safe and reliable drainage solutions.

Supporting Green Building Certifications and Sustainability Goals

SWR drainage systems are eco-friendly and recyclable, supporting green building certifications such as LEED (Leadership in Energy and Environmental Design) and IGBC (Indian Green Building Council). By choosing sustainable drainage solutions, developers can achieve sustainability goals, reduce environmental impact, and enhance brand reputation as eco-conscious builders.

Manufacturing Process of CPVC Piping Systems

Conclusion: Choosing SWR Drainage Systems for Modern Infrastructure

SWR drainage systems are revolutionizing modern infrastructure by providing efficient, leak-proof, and environmentally sustainable drainage solutions. By choosing high-quality, certified, and eco-friendly SWR systems, developers can ensure compliance with building regulations, enhance project efficiency, and achieve sustainability goals. As urbanization and environmental challenges continue to grow, SWR drainage systems are the future of modern infrastructure.

Stay on the forefront of industry trends by checking out our latest content

Stay ahead with our latest content, designed to keep you informed on the newest industry trends and insights. Discover valuable updates that help you lead in your field.

Trusted uPVC Pipes Manufacturers for India’s Top Contractors

Introduction: The Surge in Demand for uPVC Pipes Among Top Contractors in India The construction and infrastructure sectors in India have witnessed a significant transition toward sustainable and long-lasting materials.

Top Innovations in Agricultural Pipe Fittings for Water Savings [2025]

Introduction to Agricultural Pipe Fittings and Water Sustainability Agricultural pipe fittings play a pivotal role in building efficient irrigation systems, crucial for modern farming practices. By exploring the versatility of

Expeart Tips from MDPE Pipe Fittings Manufacturers to Avoid Failures

Expeart Tips from MDPE Pipe Fittings Manufacturers to Avoid Failures Understanding MDPE Pipe Fittings: An Overview MDPE (Medium Density Polyethylene) fittings, used extensively in gas and water systems, offer strong,

Request a Free Consultation

Get personalized plumbing solutions with a free consultation from Fitwell.